Initial experiments to introduce ethylene as monomer into the emulsion polymerization were done in 1950s and vae was made commercial available in the late 1960s 1.

Vae emulsoid powder poly ethylene co vinyl acetate.

More importantly our employees are experts in polymerization process technology manufacturing and application technology.

Vinyl acetate ethylene vae copolymers are formed by the copolymerization of vinyl acetate and ethylene.

We manufacture these high performance emulsions in all three major regions of the world at our facilities throughout north america europe and asia.

Vinyl acetate ethylene powders are produced from copolymerization of vinyl acetate and ethylene where the vinyl acetate is a major content falling in the range of 60 and 95 and the ethylene content in the range of 5 and 40 of the total formulation.

Celanese emulsion polymers is a global leader in vinyl acetate ethylene vae emulsions.

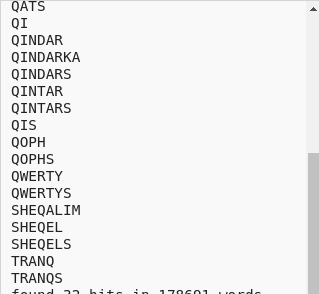

Elite mainly produce redispersible polymer powder as below.

It has some of the properties of a low density polyethylene but increased gloss useful for film softness and flexibility.

It is a copolymer and is processed as a thermoplastics material just like low density polyethylene.

Vinyl acetate ethylene copolymer emulsion vae powder elite redispersible polymer powder is produced by spray drying special water based emulsion mostly based on vinyl acetate and ethylene.

This new type of co polymer emulsions took a while to become successful outside of niche markets and on global scale.

The eva copolymer which is based on a medium proportion of va approximately 4 to 30 is referred to as thermoplastic ethylene vinyl acetate copolymer and is a thermoplastic elastomer material.

Vinyl acetate ethylene co polymer emulsions vae are one of the youngest children in the family of emulsion polymers.

It dissolves in water easily and quickly forms emulsion.

Vaes offer unique moisture resistance flexibility improved tack and adhesion in low temperature and wet conditions.